Actioning decarbonisation roadmap

The challenges of the sustainability transition are being felt across industries and value chains – and logistics is no exception. Port authorities and terminal operators can play a vital role in supporting progress towards global circularity and net-zero targets.

With regulations changing and markets demanding greener shipping solutions, the race is on for container and bulk terminals to keep up – and get ahead.

While establishing future targets for emissions reduction by a certain percentage is a good start– merely setting the goal is by no means a guarantee it will be met.

This article discusses how to transform a decarbonisation roadmap into a more concrete plan of attack.

Mapping current emissions

Understanding current emissions is key for two reasons.

- First of all, to be able to measure progress along the way. A reduction level requires a robust starting benchmark. Even though for a complete picture Scope 3 emissions are important, most reporting currently is focused on Scope 1 and 2 only. The choice of metric can also be interesting: if trade growth is foreseen it might be tempting to report emissions per unit, instead of totals. In the long run, if emissions go to net zero the end results should be the same.

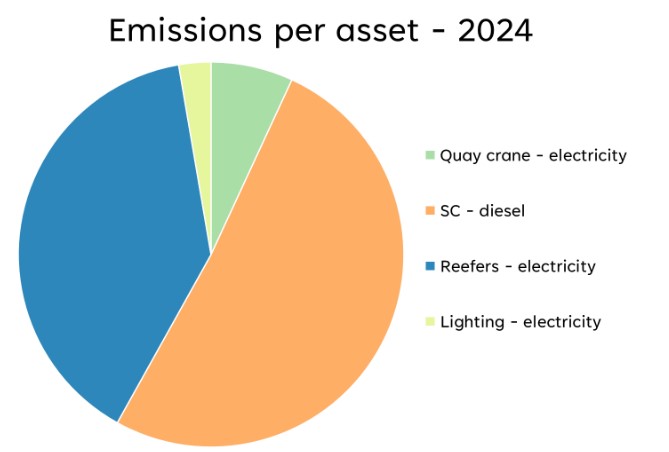

- Secondly, emissions per asset, activity or equipment also provide insight and focus. The most straightforward route to net zero is by simply replacing every piece of equipment at end of life by something as close to net zero as possible. In practice, resources may be limited, so choices may need to be made and not every euro or dollar spent will result in the same reduction of emissions.

Figure 1: Emissions per asset for a Straddle Carrier (SC) facility of 1 million lifts per year (using a CO2 emission factor per kWh of 0.36 for The Netherlands and 5% reefer volume).

The road to net zero

As stated, the most straightforward route to net zero is by replacing every piece of equipment at the end of life with something as close to net zero as possible.

In theory, an electrical option would be a good starting point – most countries have committed to reducing net emissions for energy to zero at some point in the future.

In practice, electric options may not be readily available, and the ability of the grid to provide sufficient energy/power should be evaluated as well. In some cases, electric options may not even be a good option at all, for instance for port vessels.

Most of the assets in a port environment have long life spans; an equipment purchase made now will affect your decarbonisation effort for a decade or more.

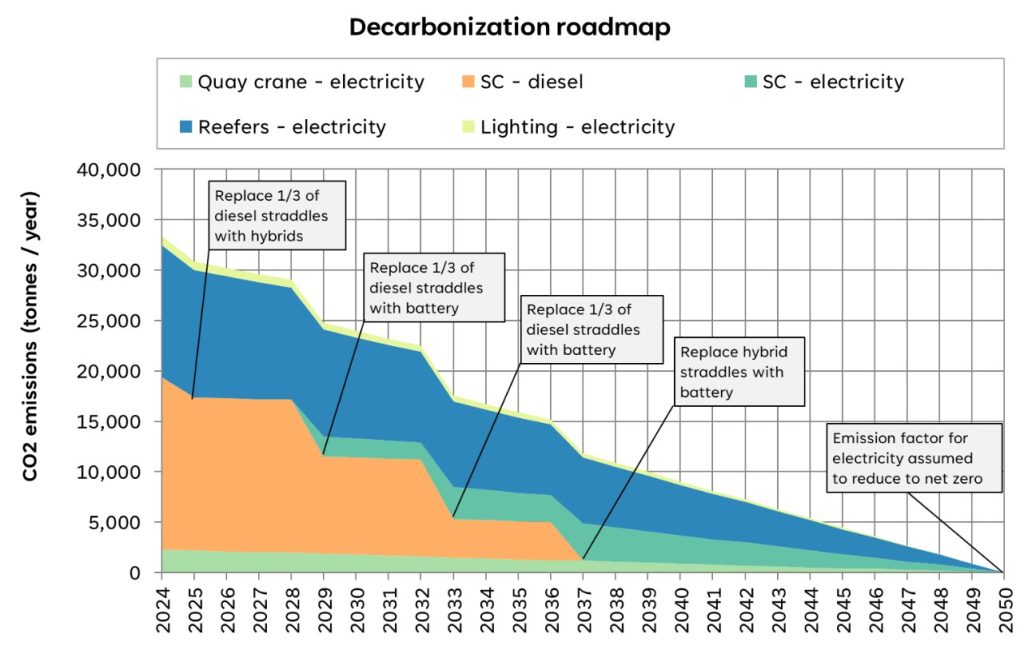

Making a roadmap for the entire period gives insight into achieving end and intermediate targets. By comparing the roadmap to actual emissions along the way, deviations from forecasted emissions, emission factors, or other variables can be tracked, and the plan updated accordingly.

Figure 2: Example emission reduction plan for a Straddle Carrier (SC) facility of 1 million lifts per year.

Figure 2: Example emission reduction plan for a Straddle Carrier (SC) facility of 1 million lifts per year.

An iterative process

Given the long-time horizon, the plan will require adjustments along the way.

- Zero emission equipment could arrive earlier or later to the market than currently foreseen, requiring or allowing changes in the equipment replacement plan.

- Changing to full electric equipment may pose challenges to the existing connection to the power grid.

- Before making the actual transition terminal operators may need to further verify if switching to electric equipment has operational impact, has requirements on on-site electrical infrastructure, requires layout adjustments, etc.

Besides, there are a lot of underlying assumptions to the emissions forecast that require validation along the way.

- Verify if actual energy consumption line up with predicted ones for new equipment

- Verify if emission level for electricity or alternative fuels are as predicted

- Adjustments may be needed for expected trade growths

In short: the emission model should allow for easy adaption of the main inputs to be able to quickly quantify the effect that changes in for example the replacement plan will have on the entire roadmap. The road to net zero is not a one-off exercise, but requires course adjustments throughout the entire period.

Some takeaways

- The typical target years for decarbonisation roadmaps are 2030, 2040 and 2050. This may seem a long-time horizon, but if the decarbonisation roadmap leans heavily on equipment replacement, procurement decisions and planning is actually “around the corner”.

- The same holds true for adjustments of layouts to accommodate operational changes and updates of the electrical infrastructure, initiating conversations with the electricity suppliers who may be dealing with many requests for significant increase in electricity demand, etc.

- From an emissions point of view going for fully electric equipment is a no-brainer, however, there are many more aspects to be taken into account.

- Apart from electrifying equipment, one can implement a continuous improvement program focused on energy efficiency.

Interested?

Portwise is at the forefront of modelling energy consumption to reduce emissions and has adopted the approach discussed in this article in their consultancy practice. For Port Otago, Portwise delivered a plan around the replacement for port assets that underpinned the port’s decarbonisation ambitions. If you are interested in exploring how this approach may benefit your port or terminal, please reach out.